In the front, there are included aluminum caster block bushings to adjust the height of the steering block relative to the arm. This is an area where the B6D differs from the B6 – the B6D comes with 0 and 3mm bushings and the B6 comes with 1 and 2mm bushings.

In the rear, there are also plastic inserts for the rear hub so that you can again raise or lower the hubs. So what is this for? What does raising or lowering the hubs do? The rear of the manual has a brief explanation, but people seem to think that the purpose of the caster hat bushings is to add or reduce steering. That’s not actually true.

The real reason to adjust the bushings is to adjust the axle height when you raise or lower the chassis ride height. Every time you want to raise or lower the ride height, you should make the corresponding change to the axle heights so that you keep the overall geometry of the arms and camber links (and steering links, and bump steer, and yada yada yada) the same. You don’t want to just change out the bushings without re-setting the ride height (or vice versa), because then you are also changing chassis angle, camber link angles, and arm angles simultaneously.

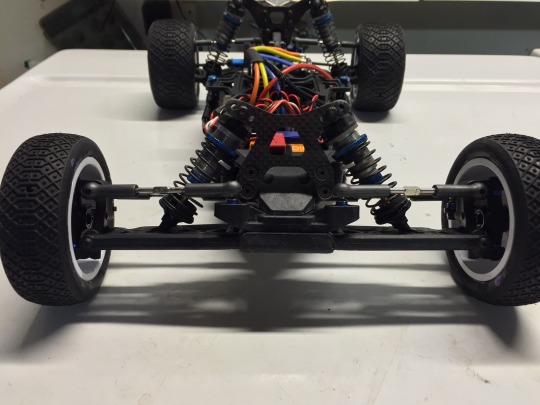

For example, this is my buggy at 23mm ride height and with the front caster bushings at the +1mm position:

The arms are nice and flat and the camber links are set to where I like them.

Now if I make a drastic change and lower the ride height to something super low, the camber links (and resulting roll center) are also going to change drastically. Take a look at the angle of the camber links when the chassis is dropped a ton in the front:

They have a massive downward angle, and you’ve effectively changed your roll center a bunch.

So the main purpose of axle height adjustment is to keep your arms relatively the same when changing ride height. Then everything else (ballstuds, camber links, etc.) will remain the same and not need readjustment or have additional effects.

Reiterating:

Front axle height

- 0 position: 3mm bushing on top, 0mm bushing on bottom

- +1 position: 2mm bushing on top, 1mm bushing on bottom

- +2 position: 1mm bushing on top, 2mm bushing on bottom

- +3 position: 0mm bushing on top, 3mm bushing on bottom

Rear axle height

- 0 position: 0/3 insert with tab on top

- +1 position: 1/2 insert with tab on top

- +2 position: 1/2 insert with tab on bottom

- +3 position: 0/3 insert with tab on bottom

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.