This review took a while to write, because I wanted to make sure I had enough experience with my buggy to provide some good information. Every time Team Associated releases a new generation of buggy, it hits the RC world like an earthquake, because they are (not) arguably the biggest seller of race buggies in the world and probably outsell all of their competitors combined.

So when Team Associated announced the B6/B6D, I immediately pre-ordered one because I knew it would be good. And not just good, but an improvement over its predecessor, already the most successful 2WD buggy on the market, the B5M.

So is it better? If so, what and why? How do you improve on one of the best, if not the best, buggy in the world?

Overview:

The B6 builds on the now-established go-to configuration for 2WD buggies – the mid-motor platform. Rear-motor is basically dead, and mid-motor is used in all conditions, from super high-grip astroturf and carpet, to very loose outdoor conditions. Two years ago, it wasn’t clear if mid-motor could work, but the RC industry has gone towards high-traction indoor tracks, and mid-motor is now the defacto weapon of choice.

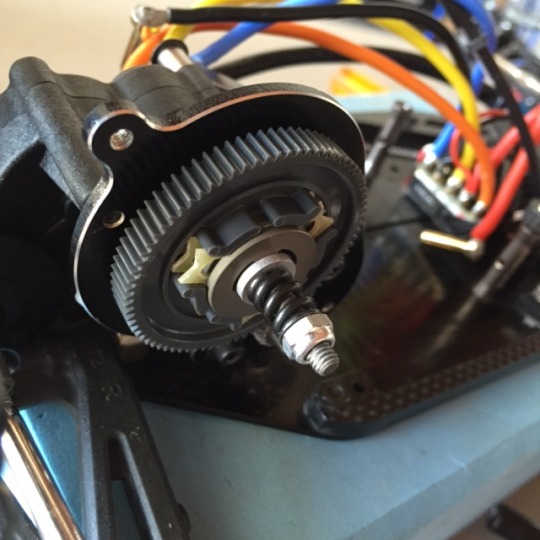

But what has changed in the last two years is that people have figured out how to adapt their buggies for high traction. Laydown transmissions give up rear forward traction for a more forward-biased weight distribution closer to 50/50. It also lowers center of gravity for higher corner speeds and less roll, and more steering.

The B6 comes in two versions, a high-grip astroturf/carpet version (B6) and a dirt version (B6D). My local track runs medium-high grip indoor clay, so I was pretty sure I wanted to run laydown transmission and got the B6. I basically set it up as a dirt buggy with laydown, but in retrospect it would’ve been cheaper to go the other way (start with a B6D) and buy a laydown.

Build: 6

My build was decent, but it didn’t go as well as my B5 and B5M builds. The manual has several errors, more-so on the B6 manual. But the AE instructions are clear otherwise and it’s a fairly straightforward build. No parts were missing, but the clear typos and incorrectly labeled screws were a letdown. Some of the plastics were really tight – the steering linkage has this issue as well as the shock pivot balls, so I have to give the build an average score.

I felt like they rushed the instructions a bit and checking the online versions a few weeks later, they still had the same errors.

Design: 9

The B6 takes an already good design in the B5M and makes it even better. The front end is no longer 4 separate pieces and goes together with only a few screws. You can remove the rear arms by only unscrewing two screws from the bottom and can instantly get at the rear inserts.

Rear inserts? Oh yeah, you now have pill inserts for both hingepins included in the box and have a bazillion combinations of toe-in and anti-squat in addition to arm width.

It has even more adjustments than the B5 – in addition to your choice of transmissions, you can now adjust axle heights both front and rear, you can get a gear diff out of the box, you can mount rear shocks fore and aft, you have more weight placement choices… it’s an astonishing amount of setup options.

Where the buggy shines is that it’s adaptable to any type of track, especially with regards to ride height and arm angle. You can tell they designed the buggy for super low ride heights all the way up to your standard 22-24mm dirt heights. The wing mounts are now buttons instead of bodyclips. The battery strap is adjustable without using foam spacers, although the 7.0mm nuts (vs. the thumbscrews on the B5M) are rather annoying and easy to lose. You now get V2 shocks as standard.

The only thing I noticed that they flubbed is that you can’t get at the motor mount screws in the laydown and the rear shock tower mount is a pain to get at if mounting shocks on the front of the arms. I had to take a Dremel to the side rail so that I could fit a 2mm hex driver on the motor mount screws.

So there are a few design choices that prevent it from getting a perfect 10 scorew, but overall the design is amazing, as usual for the latest generation of 2WD vehicles.

Performance: 10

This buggy just rocks. Out of the box, it has more steering than the B5M, with only marginally less rear traction. It jumps well, is more stable, and is extremely tunable for all conditions. The buggy is also very light, right at the ROAR minimum of 1500 grams depending on your choice of electronics and tires, or even below. With basic electronics (RX-462, Savox servo, Hobbywing XR10 justock ESC), premounted AKA wheels and tires and a full-size battery, my buggy is at 1495 grams.

In addition to the light weight, it is easier to place that weight centralized to the vehicle with the forward battery placements and forward mounted rear shocks.

The biggest performance gain is the light weight and added steering. On paper, the B6D doesn’t look like it should be much better than a B5M, but when you drive it, you immediately can go faster. Cornerspeed is where it really shines.

Durability: 10

I’ve crashed my B6 quite a bit, and haven’t broken anything yet. The shock towers are carbon now and don’t flex as much as plastic, but that hasn’t caused me any issues. The rear wing mount is more flimsy than before, but it hasn’t broken on me.

The plastics are different than the B5M. They feel lighter and less fibery, but have proven to be very durable. Another nice improvement is that the plastics wear very well. B5M arms would notoriously slop out after only 10 or so packs, but the B6 arms are tons better and I haven’t noticed any slop after 20-30 packs. Kudos to AE for making strides in this area.

Value: 8

The B6 went up in price to $309 (from $279 for the B5M Factory Lite). You get carbon shock towers and some minor aluminum bits (shock standoff bushings, bumpsteer plates, C-block brace, and kingpin inserts), but lose out on the titanium turnbuckles. It’s a fair price and inline with its main competitor, the TLR 22 3.0. It’s still cheaper than the other premium buggies, the Kyosho RB6.6, XRAY XB2, and Yokomo YZ-2, but no longer the absolute steal it once was.

Support: 10

Team Associated parts are still the easiest to find in the U.S., and they have a huge distribution and team support system in place. Setup sheets come out weekly, so its no surprise they rank number one in this area.

Dislikes:

The forward mounted shocks and laydown make the car a bit more difficult to work on, but that configuration option makes it worth it. I also find the wing buttons a little annoying, though I think they are universally lauded by everyone else.

The battery nuts are just plain dumb.

Conclusion:

The B6 is a large step forward for the 2WD buggy platform. The huge number of setup options for a variety of track types pushes the mid-motor configuration forward in a big way. The B5M was their first foray into the mid-motor market, and you can tell they’ve learned a lot about how to get the most out of that configuration and this buggy is now next generation. The light weight, adaptability, and improvement in materials make this buggy well worth it.

I was never quite able to get my B5M to drive the way I really wanted to. I like a huge amount of steering, and I had a hard time eliminating mid-corner push on the B5M without giving up on rear traction.

The B6 has loads more steering while still maintaining a lot of forward drive somehow. It’s a winner.