Gearing and timing are two adjustments you can make that have a substantial impact on speed and acceleration (and heat!). For the purposes of this post, I’m only talking about fixed timing usually adjusted by the endbell timing of a sensored motor. Some ESCs provide dynamic timing (in addition to fixed timing) that can change timing based on RPM levels (boost) or how long you are holding the throttle trigger (turbo).

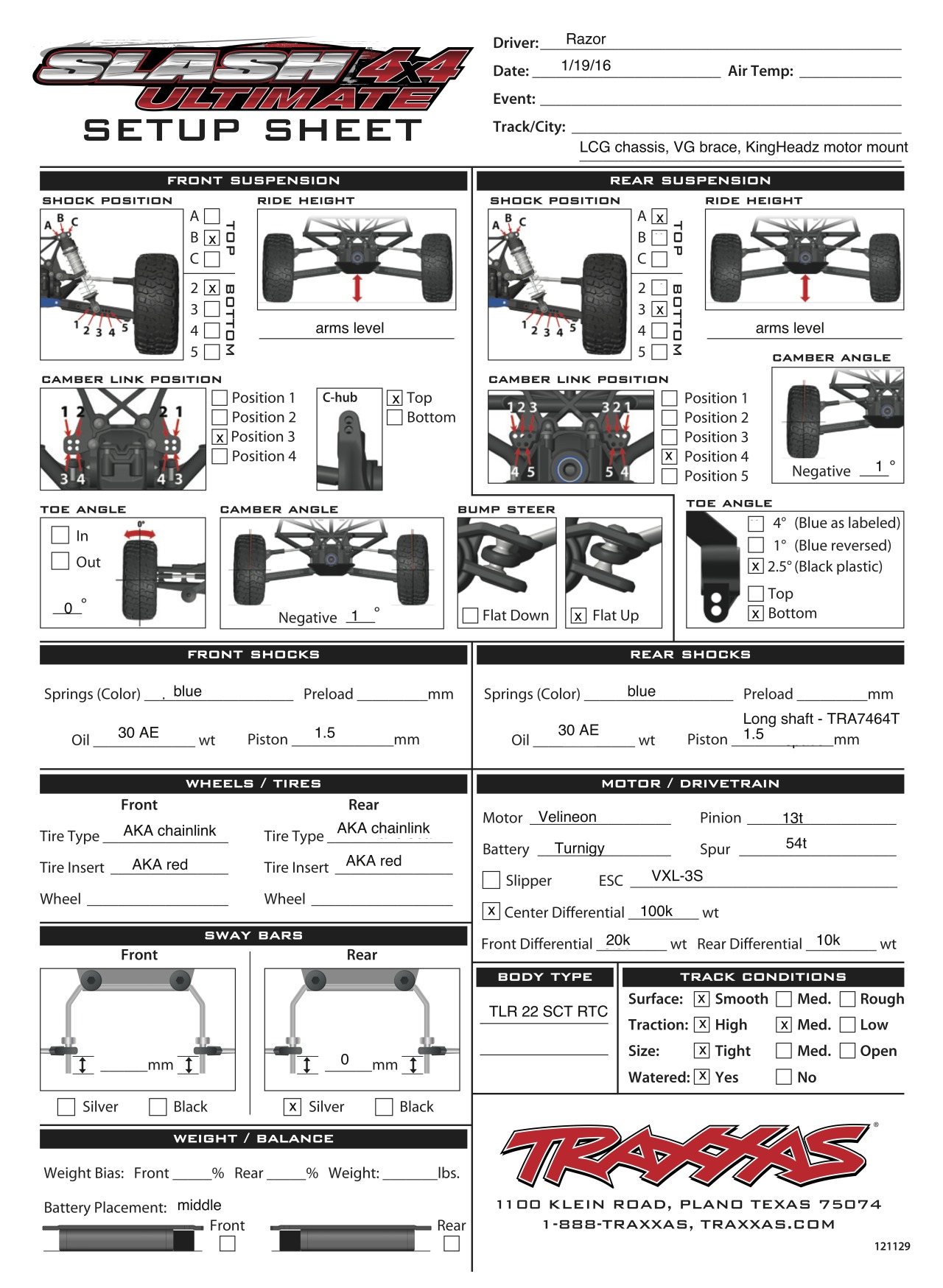

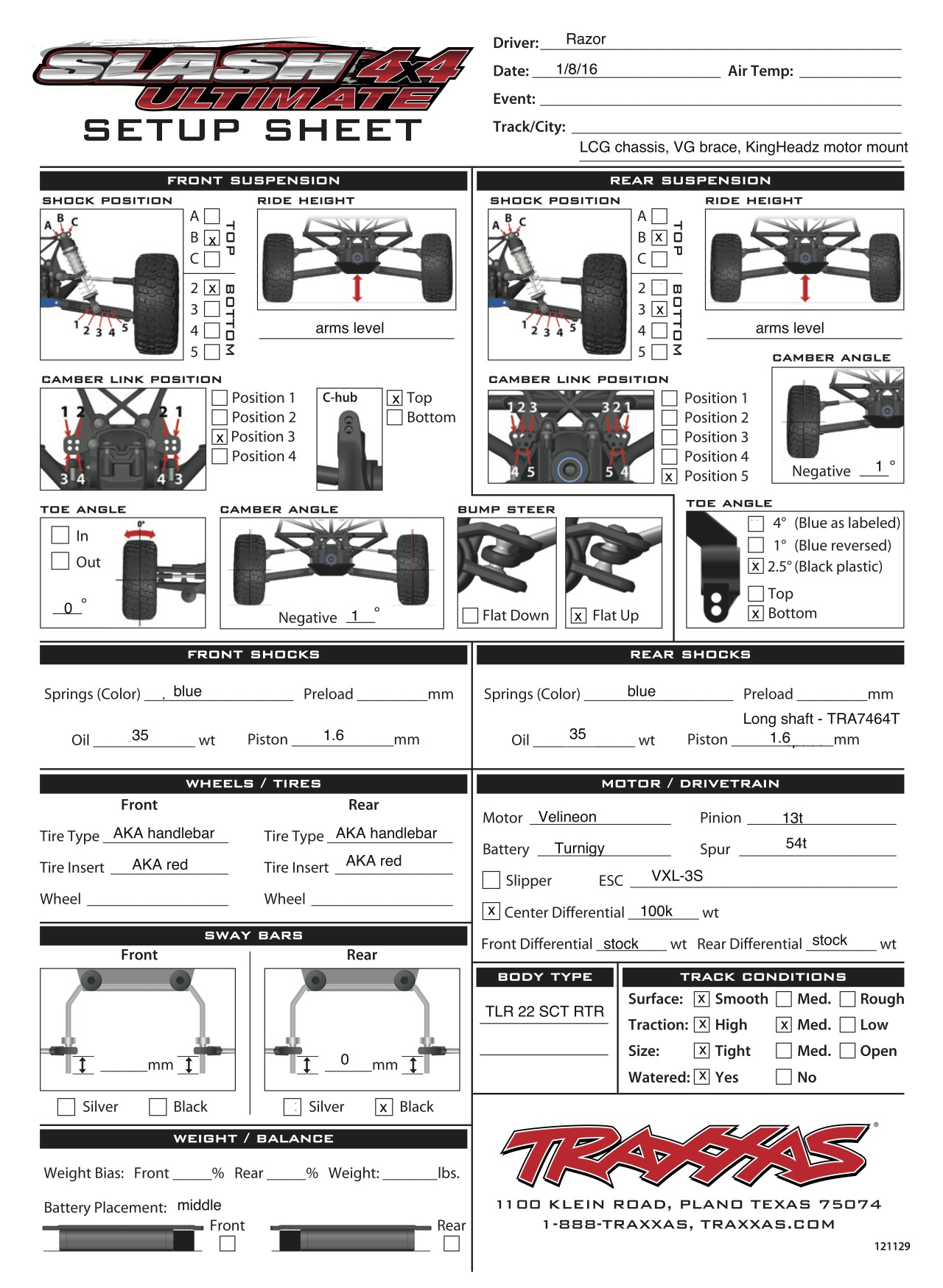

Gearing

Gearing is the more straightforward concept – basically there are two gears you can adjust:

- pinion

- bigger = higher

- smaller = lower

- spur

- bigger = lower

- smaller = higher

So obviously you can adjust your gearing on either the pinion or spur side, most people have a wide variety of pinions (since they are interchangeable on motors) and keep the same spur. Changing your spur gear is usually used to move the motor location closer or further from the rear drivetrain (to affect weight balance), or if you can’t get the gearing you want by just changing the pinion gear. Eventually if you go big enough or small enough on the pinion, you’ll run out of room and the motor won’t fit, and you’ll have to change your spur gear.

Anyone that’s driven a stick shift knows that higher gearing will allow for a higher top speed down the fast sections, at the expense of slower and more difficult acceleration from slow speeds. Lower gearing helps you accelerate from slow speeds more efficiently at the expense of lowering your top speed (or basically sitting screaming at redline and hardly getting anywhere down the front straight!).

Timing

Motors with 0 timing advancement means the ESC will send the motor pulses properly aligned with the poles of the motor. If you add timing, you are advancing the timing in relation to the position of the rotor when it is spinning.

By adding the appropriate amount of timing based on how fast the rotor is spinning, your motor will actually produce more power and run more efficiently. This has to do with electromagnetic fields and such that I really don’t understand, but the basic idea is that the faster the RPM the motor is spinning, the more timing you want to be using. The motor will produce more power at those high RPMs. The slower, the less timing you want to use.

So basically, adjusting the fixed timing moves the torque bias of the motor. Less timing will add more low-end grunt at low RPMs, and more timing will add high-end power. What this means in terms of an RC car is that you want to set your timing for the RPM you spend most of your time at when driving around the track. Most flowing racetracks will have your car spending its time high in the RPM range, so in this case you will want to add a lot of timing.

Our local track’s layout is currently rather challenging, in that it is tight, narrow, and with a lot of U-turns that go immediately into a jump. You end up doing a lot of stop-n-go’s, and as a result spend more of your time with your motor spinning slowly. I lowered my timing today as a result and got more low-end grunt to help the low speed acceleration into jumps. This hurt my high RPM power, but since the layout had very few fast sections, it was a useful trade-off.

If you get your timing set properly for the RPMs you are driving most at, you should notice the car making more power at more places on the track, and running more efficiently overall which will lower motor temperatures as well. The less efficiently you are running your motor, the more heat it produces.

Putting it together

OK, so we have some idea on what gearing and timing do, how do you use this on the track? Well, they are related, in that you will need to make adjustments to both, and you may have to adjust timing based on your gearing and vice-versa.

In general, you should set gearing for the fastest part of the track to make sure your top speed is not limited very much by gearing. It’s OK to be topped out on the front straight for a short amount of time, but if you are topped out for a very long amount of time, you will want to add gearing because you are not going as fast as you could. If you never hit the top speed or you are producing too much heat because your motor is working too hard on the slower sections, you will want to lower your gearing.

Once you’ve decided on the appropriate gearing, you’ll have to pay attention to the track and figure out what part of the RPM range you are spending most of your time. High-speed or flowing tracks where you rarely come to a stop will tend to have your motor high in the RPM range and you’ll want to use a lot of timing. Slow speed tracks with a lot of stops and slow sections and U-turns will have your motor mostly in the lower part of the RPM range, and you’ll want to reduce timing.

After setting your timing, you may need to adjust your gearing again, and vice-versa. It’s a process. An example of this is you set the gearing and your straightaways are working well. But you add timing and are now getting a better exit drive from the last corner and are now actually hitting top speed even earlier and longer. Then, you would probably want to add a tooth on your gearing and you should be screaming down the front straight!

I hope this post helped explain how to use and set your gearing and how they are related. It’s a confusing topic, but it’s something you’ll want to do every time the track layout changes. Every car, motor, and track layout change will require a different combination of timing and gearing to get the most out of your car. Not only will this make your car faster, it will also reduce motor and ESC heat if you do it right, which will prolong your electronics.

Good luck!